Kiln Repair

Furnace to Flame: A Journey In Glass

Well, I got up one morning to find that the kiln was giving an error message and would not run the program. After some digging in the manual and some online research, I came to suspect that the problem was the thermal coupler.

Disconnected

The prescribed test is to first disconnect the kiln from the power supply, then remove the thermal coupler from the kiln computer and replace it with of all things, a paper clip. If the kiln registers the room temperature when turned back on, then the thermal coupler has gone bad.

Test

The paper clip test indicated that the thermal coupler had gone bad. After scouring local sources with no luck, I had to replace the thermal coupler with the best match I could find online. The new coupler was almost a complete match and was the one being sold for this kiln. So it was ordered, and half a week later it arrived. In the meantime, I programed my larger kiln to anneal the beads and worked with it for the time period that the small kiln was down.

Fixed

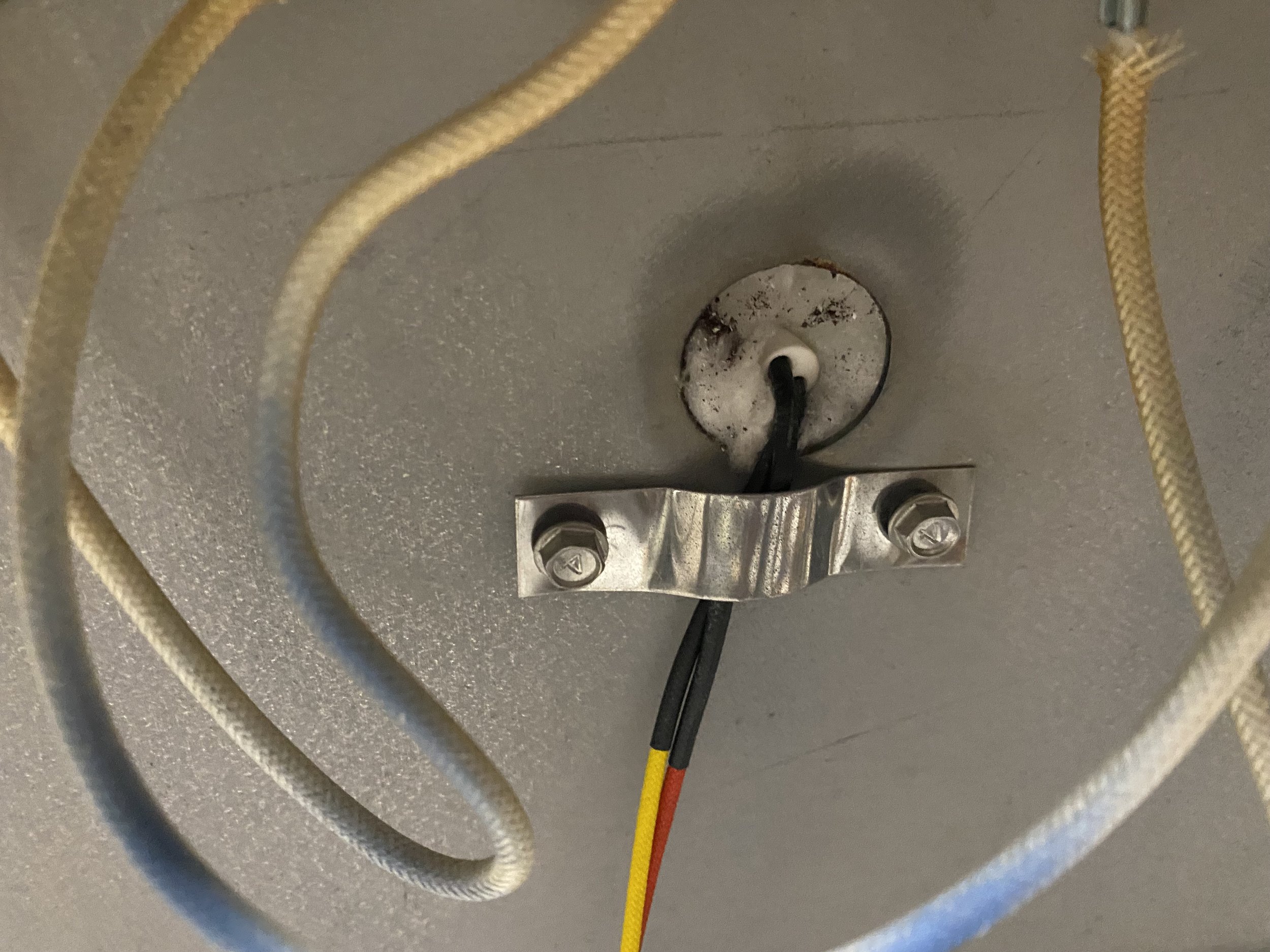

The wires were run from the coupler connected to computer.

Fixed

The coupler was secured into place and then a test was run. Everything was reading as it should.

Fixed

The back panel was secured in place.

Back In Service

The computer was secured in place and we were back in business.